Casting Process Polymer . two continuous film casting methods are typically used to manufacture biopolymer films by wet processes: casting and thermomechanical (wrought) processes use different, dedicated alloys, as casting alloys must satisfy. (a) casting on steel belt. casting refers to the process of shaping materials, such as polymers, by pouring a liquid form into a mold and allowing it to solidify. cast film extrusion allows producing technical polymer films for packaging and coating applications. the film casting process is widely used to produce polymer film: A molten polymer is extruded through a flat die, then. polymer casting is a process that involves the use of liquid polymer material, which is poured into a mold and allowed to cure or harden.

from www.slideserve.com

casting refers to the process of shaping materials, such as polymers, by pouring a liquid form into a mold and allowing it to solidify. cast film extrusion allows producing technical polymer films for packaging and coating applications. two continuous film casting methods are typically used to manufacture biopolymer films by wet processes: the film casting process is widely used to produce polymer film: polymer casting is a process that involves the use of liquid polymer material, which is poured into a mold and allowed to cure or harden. (a) casting on steel belt. A molten polymer is extruded through a flat die, then. casting and thermomechanical (wrought) processes use different, dedicated alloys, as casting alloys must satisfy.

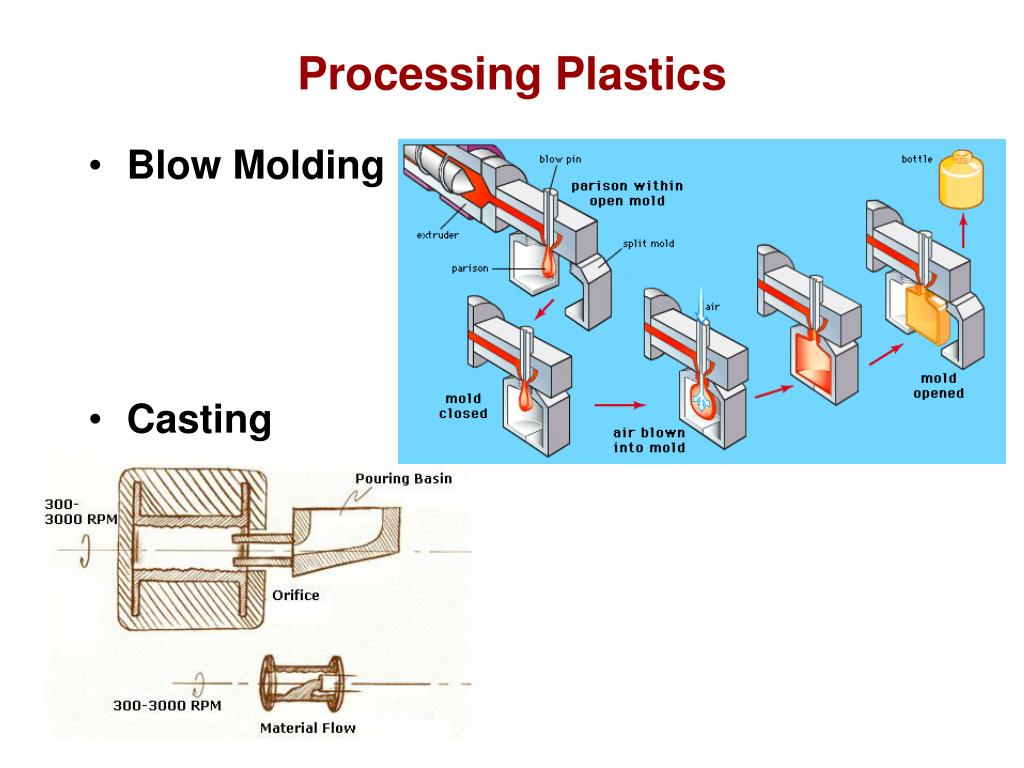

PPT Chapter 15 Polymers Characteristics, Applications, and

Casting Process Polymer casting refers to the process of shaping materials, such as polymers, by pouring a liquid form into a mold and allowing it to solidify. A molten polymer is extruded through a flat die, then. casting refers to the process of shaping materials, such as polymers, by pouring a liquid form into a mold and allowing it to solidify. cast film extrusion allows producing technical polymer films for packaging and coating applications. two continuous film casting methods are typically used to manufacture biopolymer films by wet processes: the film casting process is widely used to produce polymer film: (a) casting on steel belt. polymer casting is a process that involves the use of liquid polymer material, which is poured into a mold and allowed to cure or harden. casting and thermomechanical (wrought) processes use different, dedicated alloys, as casting alloys must satisfy.

From www.youtube.com

3 Easy Steps for Casting a Polymer Film for IR Analysis YouTube Casting Process Polymer casting refers to the process of shaping materials, such as polymers, by pouring a liquid form into a mold and allowing it to solidify. casting and thermomechanical (wrought) processes use different, dedicated alloys, as casting alloys must satisfy. A molten polymer is extruded through a flat die, then. two continuous film casting methods are typically used to. Casting Process Polymer.

From www.youtube.com

The expanded polystyrene casting process Expandable Mold Casting Casting Process Polymer A molten polymer is extruded through a flat die, then. two continuous film casting methods are typically used to manufacture biopolymer films by wet processes: polymer casting is a process that involves the use of liquid polymer material, which is poured into a mold and allowed to cure or harden. cast film extrusion allows producing technical polymer. Casting Process Polymer.

From www.plasticmoulds.net

Various Plastic Molding Process Casting Process Polymer casting and thermomechanical (wrought) processes use different, dedicated alloys, as casting alloys must satisfy. casting refers to the process of shaping materials, such as polymers, by pouring a liquid form into a mold and allowing it to solidify. the film casting process is widely used to produce polymer film: cast film extrusion allows producing technical polymer. Casting Process Polymer.

From www.youtube.com

Polymer casting YouTube Casting Process Polymer A molten polymer is extruded through a flat die, then. casting refers to the process of shaping materials, such as polymers, by pouring a liquid form into a mold and allowing it to solidify. two continuous film casting methods are typically used to manufacture biopolymer films by wet processes: cast film extrusion allows producing technical polymer films. Casting Process Polymer.

From www.theengineerspost.com

15 Different Types of Casting Process Explained [with PDF] Casting Process Polymer the film casting process is widely used to produce polymer film: two continuous film casting methods are typically used to manufacture biopolymer films by wet processes: casting refers to the process of shaping materials, such as polymers, by pouring a liquid form into a mold and allowing it to solidify. (a) casting on steel belt. A molten. Casting Process Polymer.

From www.researchgate.net

Schematic representation of the edible film formulation (A) Casting Casting Process Polymer (a) casting on steel belt. polymer casting is a process that involves the use of liquid polymer material, which is poured into a mold and allowed to cure or harden. casting refers to the process of shaping materials, such as polymers, by pouring a liquid form into a mold and allowing it to solidify. two continuous film. Casting Process Polymer.

From www.researchgate.net

Flow chart of a solvent casting method for biodegradable film Casting Process Polymer polymer casting is a process that involves the use of liquid polymer material, which is poured into a mold and allowed to cure or harden. two continuous film casting methods are typically used to manufacture biopolymer films by wet processes: casting refers to the process of shaping materials, such as polymers, by pouring a liquid form into. Casting Process Polymer.

From cezgreya.blob.core.windows.net

Casting Method Solution at Denyse Laird blog Casting Process Polymer the film casting process is widely used to produce polymer film: casting refers to the process of shaping materials, such as polymers, by pouring a liquid form into a mold and allowing it to solidify. A molten polymer is extruded through a flat die, then. casting and thermomechanical (wrought) processes use different, dedicated alloys, as casting alloys. Casting Process Polymer.

From www.omicroncasting.com

5 Different Methods Used in Casting Casting Process Polymer polymer casting is a process that involves the use of liquid polymer material, which is poured into a mold and allowed to cure or harden. two continuous film casting methods are typically used to manufacture biopolymer films by wet processes: the film casting process is widely used to produce polymer film: (a) casting on steel belt. . Casting Process Polymer.

From www.engineeringclicks.com

Centrifugal Casting process overview EngineeringClicks Casting Process Polymer cast film extrusion allows producing technical polymer films for packaging and coating applications. polymer casting is a process that involves the use of liquid polymer material, which is poured into a mold and allowed to cure or harden. casting and thermomechanical (wrought) processes use different, dedicated alloys, as casting alloys must satisfy. the film casting process. Casting Process Polymer.

From www.researchgate.net

a Solvent casting/particulate leaching process The polymer is Casting Process Polymer (a) casting on steel belt. the film casting process is widely used to produce polymer film: casting refers to the process of shaping materials, such as polymers, by pouring a liquid form into a mold and allowing it to solidify. A molten polymer is extruded through a flat die, then. cast film extrusion allows producing technical polymer. Casting Process Polymer.

From www.researchgate.net

Schematics of IPMC polymer membrane manufacturing method, (a) solution Casting Process Polymer (a) casting on steel belt. casting and thermomechanical (wrought) processes use different, dedicated alloys, as casting alloys must satisfy. two continuous film casting methods are typically used to manufacture biopolymer films by wet processes: cast film extrusion allows producing technical polymer films for packaging and coating applications. the film casting process is widely used to produce. Casting Process Polymer.

From www.diecastingcompany.com

Ten Kinds Casting Processes In Foundries Minghe Casting Casting Process Polymer polymer casting is a process that involves the use of liquid polymer material, which is poured into a mold and allowed to cure or harden. casting and thermomechanical (wrought) processes use different, dedicated alloys, as casting alloys must satisfy. A molten polymer is extruded through a flat die, then. casting refers to the process of shaping materials,. Casting Process Polymer.

From www.mdpi.com

Polymers Free FullText Selected Biopolymers’ Processing and Their Casting Process Polymer (a) casting on steel belt. casting and thermomechanical (wrought) processes use different, dedicated alloys, as casting alloys must satisfy. two continuous film casting methods are typically used to manufacture biopolymer films by wet processes: A molten polymer is extruded through a flat die, then. casting refers to the process of shaping materials, such as polymers, by pouring. Casting Process Polymer.

From compositeslab.com

Cast Polymer Molding Processes CompositesLab Casting Process Polymer casting and thermomechanical (wrought) processes use different, dedicated alloys, as casting alloys must satisfy. A molten polymer is extruded through a flat die, then. the film casting process is widely used to produce polymer film: polymer casting is a process that involves the use of liquid polymer material, which is poured into a mold and allowed to. Casting Process Polymer.

From www.mtu.edu

Polymer Processing Institute of Materials Processing Michigan Tech Casting Process Polymer casting refers to the process of shaping materials, such as polymers, by pouring a liquid form into a mold and allowing it to solidify. casting and thermomechanical (wrought) processes use different, dedicated alloys, as casting alloys must satisfy. two continuous film casting methods are typically used to manufacture biopolymer films by wet processes: polymer casting is. Casting Process Polymer.

From www.researchgate.net

Process scheme of monolith preparation by solutionbased freeze casting Casting Process Polymer (a) casting on steel belt. the film casting process is widely used to produce polymer film: polymer casting is a process that involves the use of liquid polymer material, which is poured into a mold and allowed to cure or harden. casting and thermomechanical (wrought) processes use different, dedicated alloys, as casting alloys must satisfy. casting. Casting Process Polymer.

From www.researchgate.net

Solution casting technique used to prepare the dynamic polymer films Casting Process Polymer the film casting process is widely used to produce polymer film: (a) casting on steel belt. two continuous film casting methods are typically used to manufacture biopolymer films by wet processes: A molten polymer is extruded through a flat die, then. cast film extrusion allows producing technical polymer films for packaging and coating applications. casting and. Casting Process Polymer.